Explosion Suppression Systems

An explosion suppression system consists of three components: a detector; control unit; and suppressor(s). In the event an ignition occurs, the fireball expands from the ignition kernel with the pressure wave (created by the increase in temperature) traveling ahead of the flame front. Explosion pressure detectors are configured to respond to the characteristic pressure increase within milliseconds.

The explosion suppression control unit receives the detection signal from the pressure sensors and sends a release signal to the explosion suppressor(s). Suppressant is injected into the protected vessel at high rate and high velocity, using specially designed nozzles to disperse the suppressant and engulf the growing fireball. This rapidly cools the fireball, mitigating further combustion and reducing the explosion pressure. Integral to the design of most explosion suppression system is a chemical or mechanical explosion isolation systems to reduce the risk of flame/explosion propagation to other connected process equipment.

Explosion Isolation Systems

Explosion isolation systems are designed to detect an explosion in a process vessel, and then create a barrier that reduces the risk of the flame/explosion propagation to other interconnected equipment. Such explosion propagation is likely to give rise to an enhanced (more intense) explosion in any connected vessel than would be expected from a simple ignition in that vessel. Explosion isolation is a proven method of reducing the risk of such enhanced explosions, and may be an essential requirement to attain a sufficient risk reduction from the overall explosion protection system.

Explosion isolation can be applied to vessels that are protected by containment, suppression or venting systems. There are three basic types of explosion isolation systems:

• Chemical Isolation – Discharges an explosion suppressant into the duct work that will suppress the propagating flame front, reducing the likelihood of it reaching interconnected equipment or plant areas.

• Active Mechanical Isolation – Triggers the release of a high-speed valve to form a mechanical barrier in the pipeline. Mechanical barriers provide protection against flame AND pressure propagation into connected equipment. A control panel and explosion detector are required as part of this system.

• Passive Mechanical Isolation – An in-duct valve which closes as a reaction to the explosion pressure wave can be used for isolation of interconnected ducts of process vessels equipped with explosion protection. No additional controls or sensors are usually required.

Explosion Venting Systems

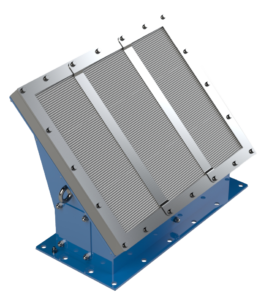

Explosion venting entails the incorporation of a frangible panel or membrane into the top or side of process plant equipment so that the overpressure of an explosion is released into the atmosphere. Venting is a proven explosion protection strategy where it can be safely applied.

For many years the most common explosion protection strategy was venting. Used correctly, explosion venting remains a viable strategy. While venting is usually the most cost effective method of explosion protection, there are circumstances where venting is impractical and explosion suppression a preferable option.

Since the goal of explosion venting is to release the explosion overpressure before the process vessel is damaged, burnt and unburnt dusts and vapors are released through the vent opening. The ejected fireball, with a typical volume eight times or more larger than the vessel volume, must be released to a safe area. It is important to note that since explosion venting only relieves the deflagration pressures from the vented process vessel, post-explosion fires are to be expected. Appropriate fire control measures should be incorporated into the process plant safety design. In addition, explosion propagation through connected ductwork is likely to occur, so explosion isolation is required.